Lean Six Sigma Inside Out

- Be unready to blablabla

- Improve your effectiveness with fact based decision making

- Strengthen your readiness to face data-driven technical problems

- Develop insights in the dynamics of high performance teams

- Increase your personal leadership and communicative skills

Watch our video about the LSS-training here

In recent decades the Lean Six Sigma methodology has made an impressive impact on the Automotive industry. Driven by the achieved results, it has made his intrance in many other fields like motorsports, the semi-conductor industry, aerospace engineering and even nontechnical industries like services, finance, healthcare and education. This course will go back to the Lean Six Sigma roots. We will build Automotive production plants and engage in a competition. Are you ready to apply the tools to your professional environment?

Program

This course is designed to train the participants in such a way that they are competent and motivated to select and apply the Lean Six Sigma tools immediately after returning to their job environment. For this purpose, the complete 10 day program is structured along a coherent project on black belt level. Distinctive results are achieved by providing the participants with tools to enhance both cognitive and communicative skills at the same time. The main training methods are just-in-time learning, pressure cooker lectures, integrative learning, working in small groups, peer-to-peer learning and gamification.

Day 1-2: Data driven process analysis

First, the focus is on building effective teams. These teams start working on product quality by applying basic tools to simple processes.

Day 3-4: Prototype design and realization

Then, the teams are challenged to apply Design For Six Sigma tools to realize multi variable machines for superior product quality. For this, effective communication and brainstorming techniques are key success factors.

Day 5-6: Multi variable process analysis

In this part, the teams learn to deep dive into the Lean Six Sigma tools to optimize the output quality of their multi variable machines.

Day 7-10: Lean process optimization

Once quality is clear, the participants are challenged to optimize their production lines by applying the Lean philosophy. The course finishes with a competitive event.

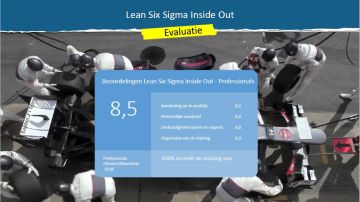

See the results of our professional evaluation

The course is designed for..

- Researchers, engineers, project leaders and managers who are new to Lean Six Sigma

Required prior knowledge is high school level mathematics (wiskunde A of B op Havo/VWO niveau of MBO-4).

The main course language will be Dutch. The instruction material is in English.

Body of knowledge

Supported by experts and coaches, the participants will learn, teach and apply the following tools.

Cognitive:

Minitab, Visual Management, PDCA, Hoshin, First Time Right, Gauge R&R, Control charts, Capability, DMAIC, SPC, Benchmarking, DoF analysis, DOE, ANOVA, Hypothesis testing, VSM, CTQ flowdown, QFD, Lean principles, OEE, Kanban, Root Cause Analysis, Ishikawa, 8D, 5xWhy, 5S, MSA, ToC, FMEA, PPAP and KPI's.

Communicative:

Disc, Team development, Feedback, Brainstorming, Visualization and Deep Democracy.

Partners and tools